What is Nanotechnology?

According to the EC, nanomaterial means any material containing loose particles or in the form of aggregate or agglomerate, and in which 50% or more of those particles in the numerical granulometry have at least one of its dimensions in the size range between 1 and 100 nanometers. According to the number of dimensions at the nanoscale, three types of nanomaterials are distinguished: nanoparticles, nanofibers and nanoplates, depending on whether they are 3, 2 or 1 dimension in the nanoscale respectively. For many years, nanomaterials have been produced by industry, although they canbe found either in nature or result from human activity.

Due to their small size, nanomaterials are governed not by the laws of classical mechanics, but by those of quantum mechanics, so that matter exhibits completely new properties. This is generally because nanoparticles have a greater surface area per weight than larger particles; they are therefore more reactive to some other molecules. For example studies have shown that nanoparticles of iron can be effective in the cleanup of chemicals in groundwater because they react more efficiently to those chemicals than larger iron particles. Thus, nanomaterials can have chemical, physical, electrical and mechanical properties more marked than those of the same material in the macroscale. These properties make them particularly suitable for many applications. They can enhance properties such as strength, durability, electrical conductivity, antimicrobial capacity, structural capabilities, thermal and chemical resistance, barrier to oxygen and moisture, low wear and friction, flame retardancy or flexibility.

For instance, nanoparticles are used increasingly in catalysis to boost chemical reactions. This reduces the quantity of catalytic materials necessary to produce desired results, saving money and reducing pollutants. Two other big applications are in petroleum refining and in automotive catalytic converters.

Nanomaterials and main applications

Nanomaterials are very useful in many applications, and are used in almost all industrial sectors and product categories.

The nanomaterials mainly used at industrial level are: nanoclays, CaCO3, multiwall carbon nanotubes, carbon nanotubes, SiO2, Al2O3, ZnO, TiO2, Sb2O5, SnO2, silver, gold, nanocellulose and graphene.

In additives field, nanomaterials are used in the production of coatings, paints, lacquers, inks, fabrics, textiles or spots equipment to improve, mainly, resistance properties, to facilitate manufacturing, or to give antibacterial properties. In the plastic sector, and specifically in packaging, they are widely used due to the great amount of properties they are able to improve (electrics, thermal, resistance, process, hygiene ...), for instance for the production of antimicrobial food packaging or to reinforce polymers. One of the most common well-known uses of the nanotechnology is its application in automotive and aerospace industry. Nanomaterials can reduce chassis materials weight, improve glass quality, allow to obtain more efficient catalysts, be used as fuel additives, or enhance energetic efficiency of battery systems. ENMs are very useful in constructions too, since they increase the strength and stability of materials. Nanotechnology provides also great advantages in the energy sector, by using nanomaterials in nanostructured solar cells, catalysts, or films, among others. Nanostructured membranes are used in wastewater treatment, as well as to improve air quality. One of the most recent uses of nanotechnology is the improvement of crops and the release of fertilizers and other agrochemicals. They are able to enhance definition or flexibility in electronic devices too. Carbon nanotubes or graphene are widely used to improve electrical and thermal properties in electronics. Medical applications and cosmetics and personal care products are another one of the application target market of nanotechnology, due to the antibacterial and antimicrobial activity and UV barrier properties. In addition, more and more nanotechnology is being used in other more complex applications, like the production of prostheses and in bone or neural tissue engineering.

Nanomaterials and the plastic sector

The use of nanotechnology in plastics involves the use of nanomaterials in all their different forms: nanoparticles, nanoplates and nanofibers. Therefore, there are new business opportunities for the industry, mainly derived from the manufacture of nanocomposites (Grand View Research, 2015).

Nanocomposites are polymers reinforced with particles that have one or more dimensions of the order of 100 nanometers or less, enabling the development of new plastic materials with oxygen barrier properties, heat resistance, improved dimensional stability or mechanical performance.

Engineered nanomaterials can be used in both polymer matrix: in thermoplastics (which soften on heating and then harden again on cooling), and in thermosets (which never soften when molded).

The incorporation of nanofillers into polymer composites means a range of improved properties into plastic based materials. Those nanofillers are typically inorganic materials such as metals (aluminum, iron, gold or silver), metal oxides (zinc oxide, aluminum oxide or titanium dioxide), mixed metal oxides, carbon nanotubes (CNTs) and nanoclays.

Concerns

Precisely because of their extensive use, exposure to nanomaterials can occur throughout the life cycle of a given product, from production to consumers, and of course to their final release to the environment. This exposition may happen in very different ways.

Workers are exposed when they manipulate nanomaterials, either in the same synthesis, or as raw materials in the manufacture of other types of products. Consumers, for their part, may be exposed by contact with products containing nanomaterials. However, this does not mean that all products produced by nanotechnology contain nanoparticles that can be released during consumption. Exposure to the environment would mainly occur at the end-of-life product, when it becomes a waste.

Engineered nanomaterials exhibit unique physical and chemical properties which are different from those demonstrated by the same materials in bulk form. Precisely for this reason, the risk assessment of these substances must be different from the one applied in the same materials in the macro-scale (Jones et al. (2015); Mouneyrac et al. (2015)).

Just like any other chemical substance, some nanomaterials are hazardous and others not. The nanoscale of the particles does not imply hazard as such. Instead the potential effects are based on the inherent toxicological properties, on the quantity (dose) taken up by an organism (humans or an animal), and finally on the exposure to the nanoparticles.

Despite the large number of studies, the uncertainty is still high because of the wide range of properties and their interaction with biological processes, both very different from those of the same bulk substance. The risks to human health and the environment depend on various factors, such as shape, size, type or coating. Due to the great variety of nanomaterials in the market, the best way to study the potential risk of nanomaterials is case by case. Therefore, concerns have been raised about the adequacy of existing regulation in Europe and what should be done to address any potential regulatory gaps related to nanomaterials (Hansen et al. (2012)).

Human health risks

One of the most important uncertainties associated with nanofillers is related to the risks arising from occupational exposure. The potential routes of exposure to ENPs in the working environment include inhalation, dermal and oral (Amoabediny et al. (2009)), although inhalation is the most critical pathway during human exposure to a nanostructured aerosol (Cesard et al. (2913); Evans et al. (2013)), as well as the most common.

Many tasks require the manual handling of nanomaterials in dusty form, contributing to the potential exposure of the worker to NPs (Gomez et al. (2014)). Assessing the worker exposure to NPs is quite challenging due to the fact that conventional exposure monitoring techniques may not adequately characterize nanomaterials (Abbott et al. (2010)). Besides, it involves a multifaceted approach, incorporating many different sampling techniques (Methner et al. (2010)).

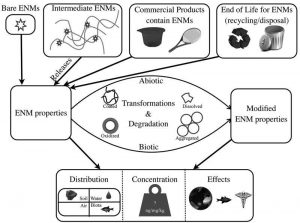

During manufacturing, some activities and ENMs are more likely to release nanoparticles than others. For example, processes involving the manipulation of NMs in dry or powdered form will emit higher concentrations then the ones in liquid or humid state. However, not only workers are exposed to engineered nanoparticles, but consumers are too. So, exposure assessments for engineered nanoparticles should cover all the identified uses for the entire life-cycle of the individual nanoparticle, from the synthesis and production of the ENM, functionalization, incorporation or use of the ENM, utilization of the final product and disposal or recycling.

For the identification of polymer nanocomposites risk, it is necessary to rely on whether the nanofillers will detach form the original polymer during normal conditions of use and/or end-of-life treatments.

Environmental risks

Engineered nanomaterial production, use and disposal lead to environmental release of ENMs (Gottshalk et al. (2011)), and ultimately accumulate in the soil, water or biota, endangering the health of living organisms and ecosystems (Kolher et al. (2008)). For instance, wastewater treatment streams, landfill leachates, or waste incineration products are all likely to contain ENMs from nanoenabled products disposed of at the end of their useful life. The biggest risks come from atmospheric emissions and solid or liquid waste streams from production facilities. Similarly, the release of ENMs from commercial products as paints and personal healthcare, including sunscreens and cosmetics, enter the environment proportionally to their use (Biswas et al. (2005)). Moreover, intentional release into the environment must be considered, since nanotechnology is also used for contaminated soils remediation or on groundwater polluted treatment with chemicals (Nowack et al. (2007)).

Figure 1 shows the main routes of release and fate of nanomaterials during their life cycle to different compartments of the environment.

The toxicity and ecotoxicity of these nanomaterials is directly related to their structural properties, their physico-chemical characteristics and their processes of degradation and transformation in the environment. Because of this, it is necessary to develop safety assessment approaches related to the properties and mechanisms of nanomaterials, both by themselves and in the products, to cause damage to health and the environment.